I promised you yesterday (after the Singer 66-16 showoff) -

that I had something cool for you today. And I'll tell you about it in a minute - I swear. But I want to tell you something about buying antique machines -

It's not just the machines that often need restoring and a bit of elbow grease. The machines often came in tables, cabinets, or bentwood cases, mostly made of wood. That often means being willing to restore the wood to its former glory. And then, in some cases, the machines came in treadle cabinets, where you use your foot to run the machine via a metal plate contraption on the bottom. The foot it your motor here. This part of a treadle table is made of cast iron - so you have the potential for rust issues and a necessity to repaint the iron.

Knowing all this, if you are looking for a great deal and willing to put some work into something, you can find some great projects on Craigslist.

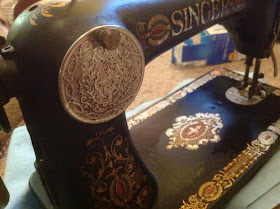

Case in point - this Singer Redeye. A Redeye is a Model 66 (the 66-16 was a derivative model) with fancy painted decals that look like red eyes on either side of the Singer logo.

The machine was in a treadle cabinet. Today I'll just tell you about the machine, then I'll get to the cabinet next post. It was getting WAY too long for one post!

I went to see this machine Monday. It's grimy, filthy, the wheel barely turns....but the decals are still there..the ones on the bed are worn, but worn like they've been used, which I like. The seller wanted $50 for the machine in the treadle cabinet, but after I saw the condition, we settled on $40. It was going to take a lot of work to make this look decent again. It was in sad shape...I was worried about my investment.

But I looked up the serial number - like I told you about yesterday - on MySingerStory? This girl was born in 1910. Let me say that again. 1910. She is 102 years old. Someone had to bring her back to life!

I got it home, and read up on everything I needed to know. A great resource is TreadleOn. Most of my information to do this came from there, paired with other blogs, message boards, eBay, Craigslist...anything I could use for information and help and value. That alone was a lot of work.

I got together a set of sewing machine cleaning tools - TriFlow Oil, Qtips, Precision screwdrivers, flat head screwdriver, tweezers, dish soap, and lots of shop towels. Oh, and a nice flashlight. It's really difficult to see inside the darkness of a black machine without it. I used WD40 as my solvent - Liquid Wrench is preferable, as it supposedly leaves less residue...but I couldn't locate it anywhere. People use WD40 on sewing machines and have no complaints - just remember it's a solvent, not a lubricant, so you have to wipe it out and re-oil the pieces when you're done. Plus, I'm only using it this first run - when I find Liquid Wrench, I'll replace the WD-40 in my tool kit.

I took the machine out of the table to work on it. You just remove the two flathead screws in the round metal pieces that attach it to the wood, and it lifts right out.

For the inside of the machine, I used precision screwdrivers (not pictured) and a regular flat head screwdriver to get inside the machine. If your screws are a bit stuck, spray some WD40 or Liquid Wrench on them and let them soak a bit, then try turned back and forth again.

Then I used cotton swabs (Q tips) and forceps (tweezers, not pictured) to remove any lint I could get to. And there was a lot.

Don't forget to clean the lint under the machine, the bobbin plate, the slide plate, and the back plate (this circle in the pic) as well.

You see the little holes on the top of the machine there? Those are the oil point holes. Clear the lint out of those as well. You may need to use a tiny flat head screwdriver to pull it out best.

See the underside? Ewww...

There's a combination of ancient oil and grease, plus what I believe is nicotine baked on.

I had to use a myriad of methods to get that in working condition. Delint, plus WD40 to get the first layer off, plus scraping some if the metal pieces to get the black baked on crud off. Bleh. That was gross.

After you get the crud out, you need to wipe it all clean with a shop rag to remove the crumbs and crud, as well as the excess WD-40. You want that gone.

Then, hit up all the oil points with the Tri-Flow oil. You just need a drop. There's points all over - if you have the manual, it will show you. If you don't have the manual, you can often find them free on the Singer website. Otherwise, you are looking for holes along the top arm of the machine - there will be a good handful of them up there. Unscrew the end plate and oil all the oil holes in there, and any point where metal parts connect and rub on each other.

There's some oil points in the bobbin winder mechanism too, and in the hand wheel. Also, in the back plate area, oil the moving parts and oil points in there as well. Don't forget the red felt in the bobbin case area.

Under the machine, there's a few oil holes in joints, and then you need to oil any metal parts that move against each other.

The I went over the outside of the machine with a dilute dish soap solution, and scrubbed the crud off. Carefully though, I didn't want the decals to rub off.

I also started oiling the outside of the machine to get the sheen back. That will take a bit of time to get shiny.

Here's the machine after:

Isn't it a huge improvement? There's still a bit of smoker's nicotine grime on the outside, but I'm working on it over time. Kills my hands to scrub so much.

Wait, you can't see the improvement? Here's the before and after:

|

| Before |

|

| After |

I successfully brought back a 102 year old sewing machine and made it work! I feel so empowered.

Next up - I'll show you how I brought the cabinet back, and then how I brought the treadle back.

Whew - It's been a lot of work.

:)

Hope this helps someone else get started!

Jess

Wow! You could have been writing of my experience with a red head! She has a manufacture date of Oct. 5, 1910. She was a $10.00 'door stop'! Perfect for me. I'm learning on her and with any luck may bring her back to life. Kinda iffy at this point. What brought me here was her decals. I'm doing some cleaning and the goldish looking part of the decal is turning silver. (only working in a small spot) That was with a cleaning wax. I think I better try some mild soap and see if I have any better luck. The poor thing is beyond nasty. Oh! And, tape...or what's left of it. I think old surgical tape that the glue has turned to CEMENT. Someone didn't know how to put the slide plate back on. It's not for a seam guide! The only nickel left on the machine is on the slide plate. The glue preserved it! Thank you so much for posting your experience!!! Gotta go read more, now!

ReplyDeleteI have the exact same Singer that I restored a few years ago. I wish I had had your blog then! Your's is in much better shape than mine. (most of the decals had already rubbed off). I use mine all the time to sew. I can't seem to get the bobbin winder quite right. No matter how many cleanings and oilings it just doesn't run smoothly, and i have to crank it why hand. Any advice? I was also super happy to discover that the hardware store near me carries a line of antique hinge screws. Perfect for the screws I managed to loose trying to fix the cabinet. Good luck!

ReplyDeleteUse ArmorAll to get the shine back

ReplyDeleteBorox is awesome at removing nicotine. Mix some in with water and dish soap. All of the Borox won't dissolve but the resulting mixture will do the job. The nicotine will just melt off. I haven't used it on any of my machines, so I would do a spot test first.

ReplyDeleteAbout to begin working on my find: a 1911 Model 66-1 (back-clamp) Singer "Red Eye"... wheels and treadle work smoothly, but the bed of the machine has decals all worn off and the black is worn off down to the bare metal. This machine was well-used! I am going to have to redo the black of the bed at least. As I take it apart I'll know more. Think I will attack the iron treadle base first. My husband has agreed to refinish the wood for me (he has more experience with wood). I'm excited to get started! My inspiration for this project is memories of the "Red Eye" my grandma had on the farm...

ReplyDeleteI finished a similar project and got some success after trying few different things. Posted a youtube video too for others who may be interested.

ReplyDeletehttps://youtu.be/iUwQn_T6LnQ

I'm possibly buying what I think is a 66. I'm a vintage Singer been. It's in a cabinet, electric, black with red eye decals, and a light behind it. I can't find anything on the internet. Typically they were treadles. I was going to ask the seller to get me serial number, but it's only $20 and not too shabby. Thoughts? Do you think it's been modified? Thanks! I'll keep ya posted.

ReplyDeleteThat's a great price, especially if it's running! I believe Singer 66s were treadle AND electric models, and you'll see them everywhere. That said, it's easy to modify a treadle machine of that era to electric - and no harm done. Feel free to ask the seller the serial, as it's fun information, but it isn't often helpful beyond detaining year or model. Good luck!

Delete